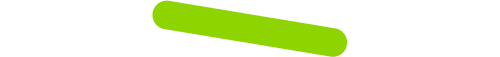

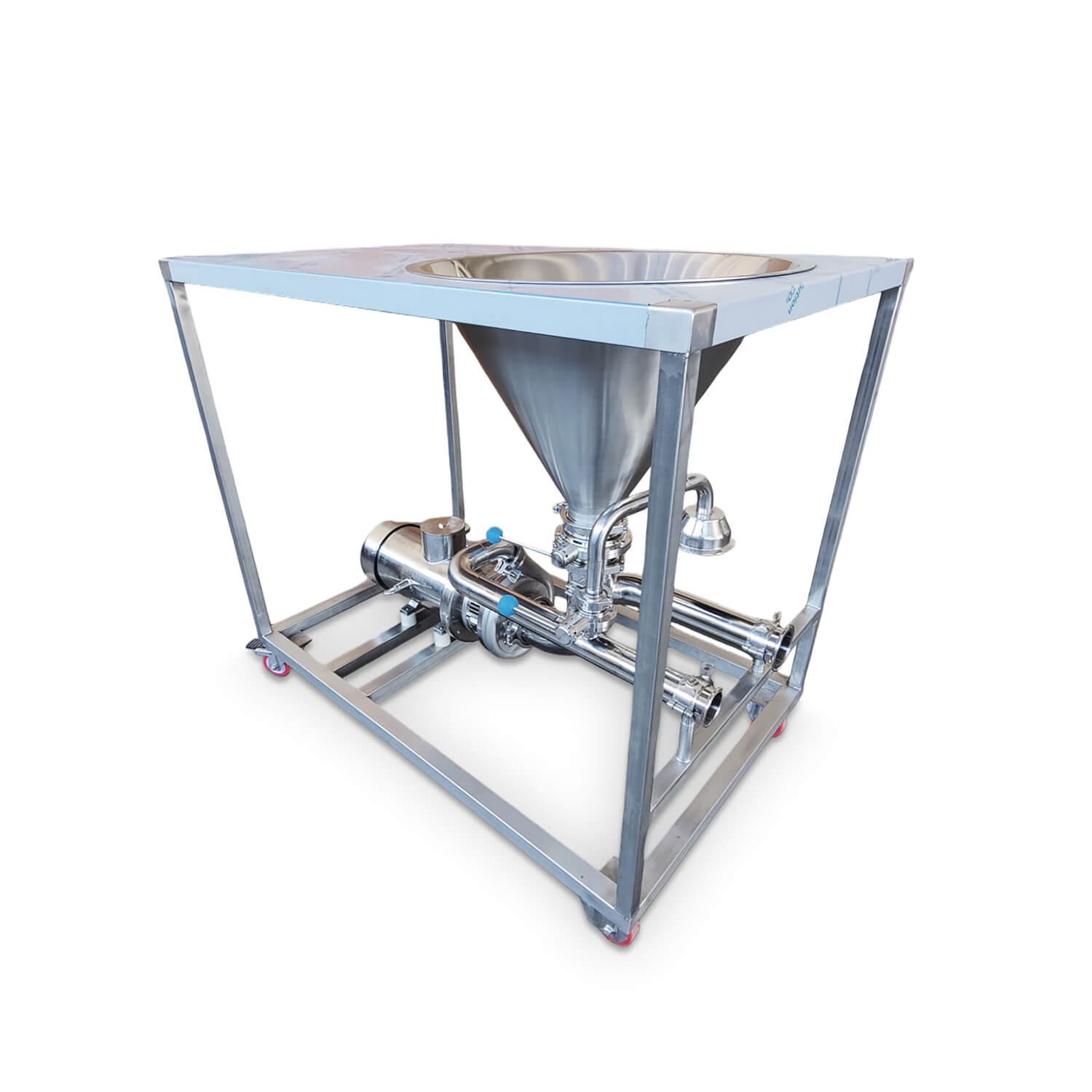

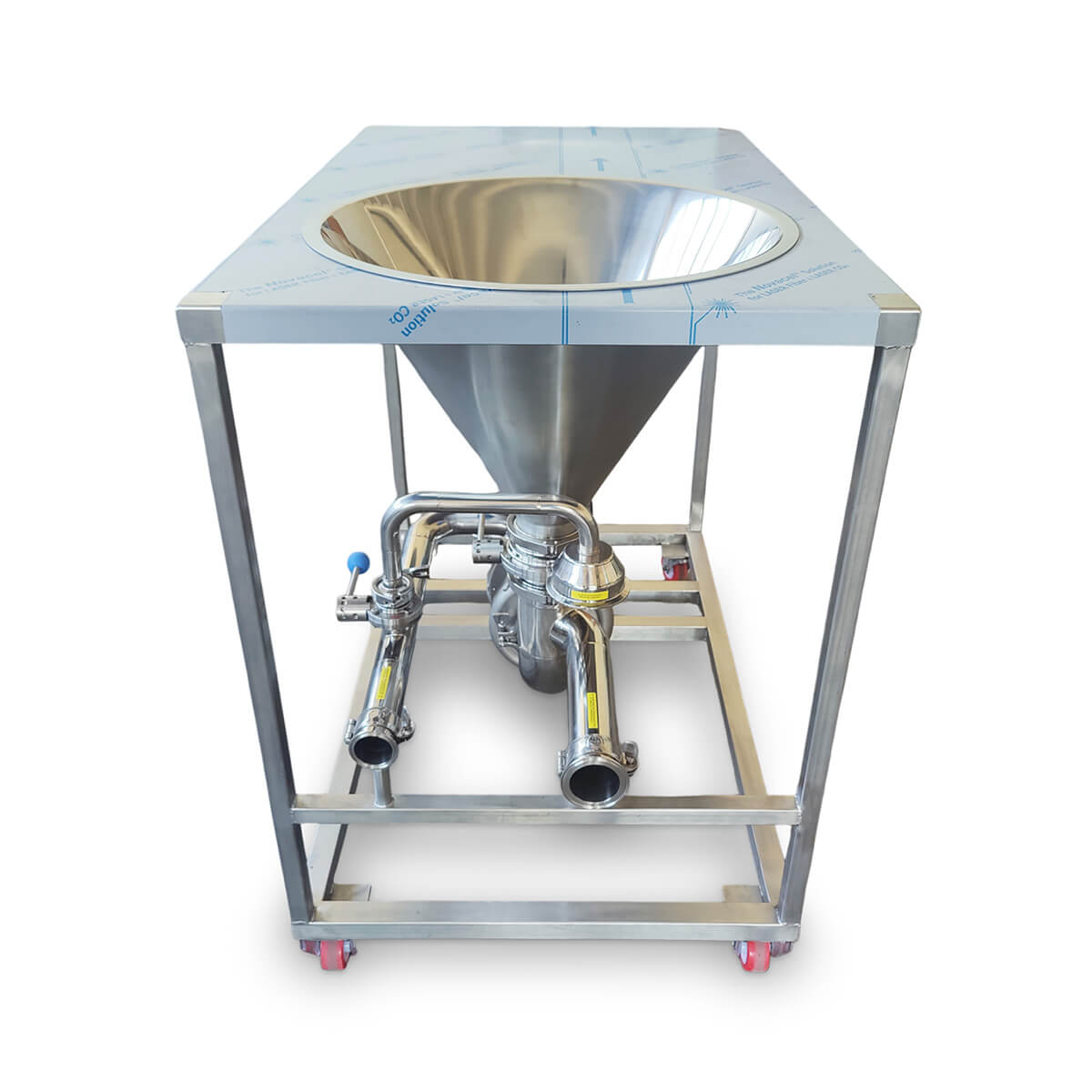

The triblender dissolver is used to dissolve solids in liquids quickly and efficiently; even independently.

The parts that come in contact with the product are all in AISI 316 L stainless steel, all elastomers are made of EPDM, a centrifugal pump with open 6-vane impeller that allows to perfectly clean and sanitize the pump body inside the volute during the washing phase.

Electric motors in IP69K stainless steel of our production to exclude the application of casings to standard motors and pursue a hygienic solution as a whole.

High production quality and robustness for long-term reliability.

The support surface allows the bags to be positioned and facilitates their unloading inside the hopper.

The AISI 316 L stainless steel hopper is built with flat sheet metal lathe and does not have unnecessary welds to raise its quality.

Operating principle::

.

The products to be dissolved are fed into the hopper.

The strong depression at the base of the hopper allows the impeller to suck the product to be dissolved, while the liquid is pumped as in a normal centrifugal pump.

At the moment of opening the hopper valve, the solids are sucked and dissolve perfectly as they pass inside the pump body.

The system enters mixing just before the inlet of the centrifugal pump suction.

A simple, affordable, very effective and reliable system for rapid and uniform mixing.

It is advisable to work in recirculation until all the solids are incorporated to have a dissolution as homogeneous as possible and that is able to keep going for a while; even after the solids have already completely dissolved.

At the end of production, by removing the hopper and connecting the washing system implemented in the delivery tube of the triblender dissolver, it is possible to wash efficiently and completely, through the built-in washing ball, the butterfly sanitary valve and the Venturi system.

The exclusive sanitary design of the triblender dissolver allows easy adaptation to mixing applications in food, beverages, dairy products, cosmetics, chemicals and pharmaceuticals.

- Reconstruction of powdered milk

- Protein additions

- Dissolution of cocoa and/or sugar in milk

- Dissolution of whey powder

- Preparations of dairy flours and starches

- Production of sugar syrups, sorbitol, glucose, lactose and derivatives

- Brine preparations

- Pre-mixing of yogurt and other milk-based desserts

- Dissolution of casein and caseinates in the dairy industry

- Preparations of pesticides and fertilizers

Characteristics:

- Standard hopper capacity 50 Kg

- Circular hopper, removable

- Suction of solids up to 50 kg/minute

- Wide range of performance with flow rates up to 40 m³/h

- Electric motors IE3, IP69K, in stainless steel, 3 and 4 KW – 2800 rpm

- Washing system integrated into the delivery that simplifies cleaning without the need to disassemble the system

- Venturi tube-in-tube system, with the possibility of removing the internal cone for total inspection

- Easy disassembly of parts thanks to clamp connections

- Complete dissolution thanks to product recirculation

- Butterfly sanitary hopper opening valve, and with handle outside the frame

- Table that can either have wheels, adjustable hygienic feet or both

On demand

- Hopper finish with certified roughness

- Electric panel made of stainless steel

- Possibility of independent operation or with additional power supply pump

- Mobile trolley version, without table

- Tables and trolleys customizable in sizes and accessories (inverter, hopper vibrator, level probes, etc…)

- Customizable suction and delivery connections

- Pump tests with inverter and the possibility of requesting the test certificate with prevalence-load and flow-absorption graph

- Customized pump curves to maximize the potential of the electric motor