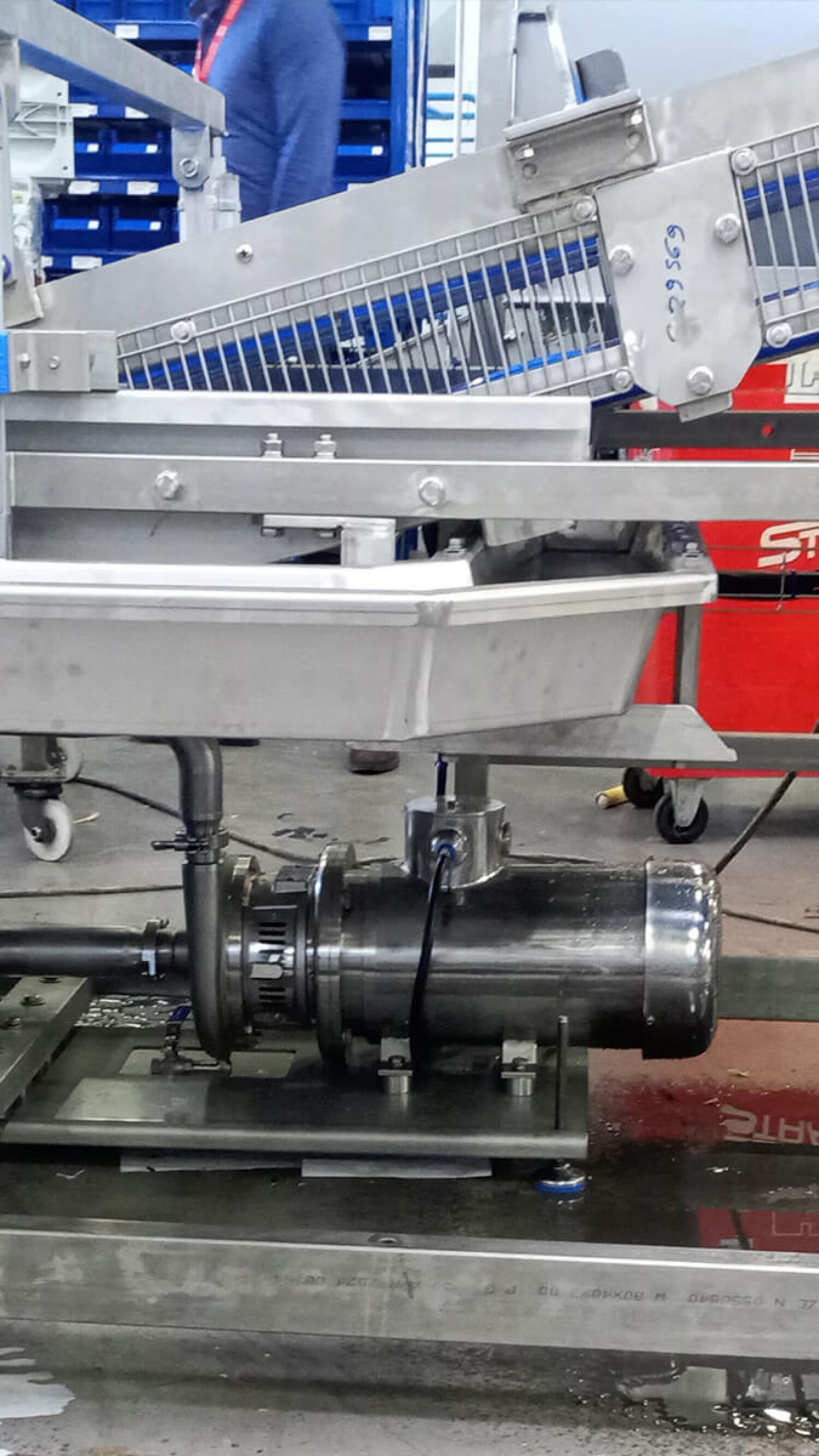

The sanitizable centrifugal pumps in AISI 316 L stainless steel are suitable for the transfer of liquids (food and beverage sectors) where effective cleaning is required for food safety. Excellent resistance against corrosion.

High production quality, robustness and reliability in the long term, considerable wear resistance, high number of revolutions, direct coupling with electric motors and low prices.

Smooth surfaces and specific seals allow to widely meet the IP69K classification (the highest degree of protection for a pump); ideal solution for CIP (Clean-in-place), SIP (Sterilization-in-place) applications and high-pressure washes (even with high-temperature water and/or with the addition of aggressive detergents), in a humid environment and in all sites where cleaning is planned on site, guaranteeing efficiency over time.

CENTRIFUGAL PUMPS

- AISI 316 L build

- Where possible, all parts in contact with the product are CNC machined with a degree of roughness RA less than 1.2 microns, ensuring a finish in accordance with the indications of hygiene standards

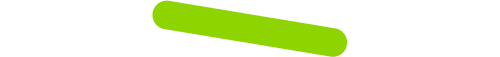

- The closing of the volute, adjustable at 45° angles, occurs through safety screws at high pressures

- Externally sanitizable pump

- Modular system of components, without welds (except in the connections)

- Rapid disassembly of the mechanical seal thanks to the removable seal holder (this means that having to disassemble the entire pump to replace the seal is no longer necessary)

- Customizable suction and delivery connections

- Adaptable and modular for both flushed car sealing and external flushing sealing (Plan 54, Plan 55, etc.)

- Open 6-vane impeller that allows to perfectly clean and sanitize the pump body inside the volute during the washing phase

- Wide range of mechanical seal materials for the different types of liquids pumped

- Applicable powers: 0.75 - 4.0KW 2Poles; IEC 80 – 112

- Degree of protection IP69K

- Operating pressures greater than 4.5 BAR

- Flow rates: 1 – 50 m³/h

- Noise: < 70 dBA up to 20 m ³/h

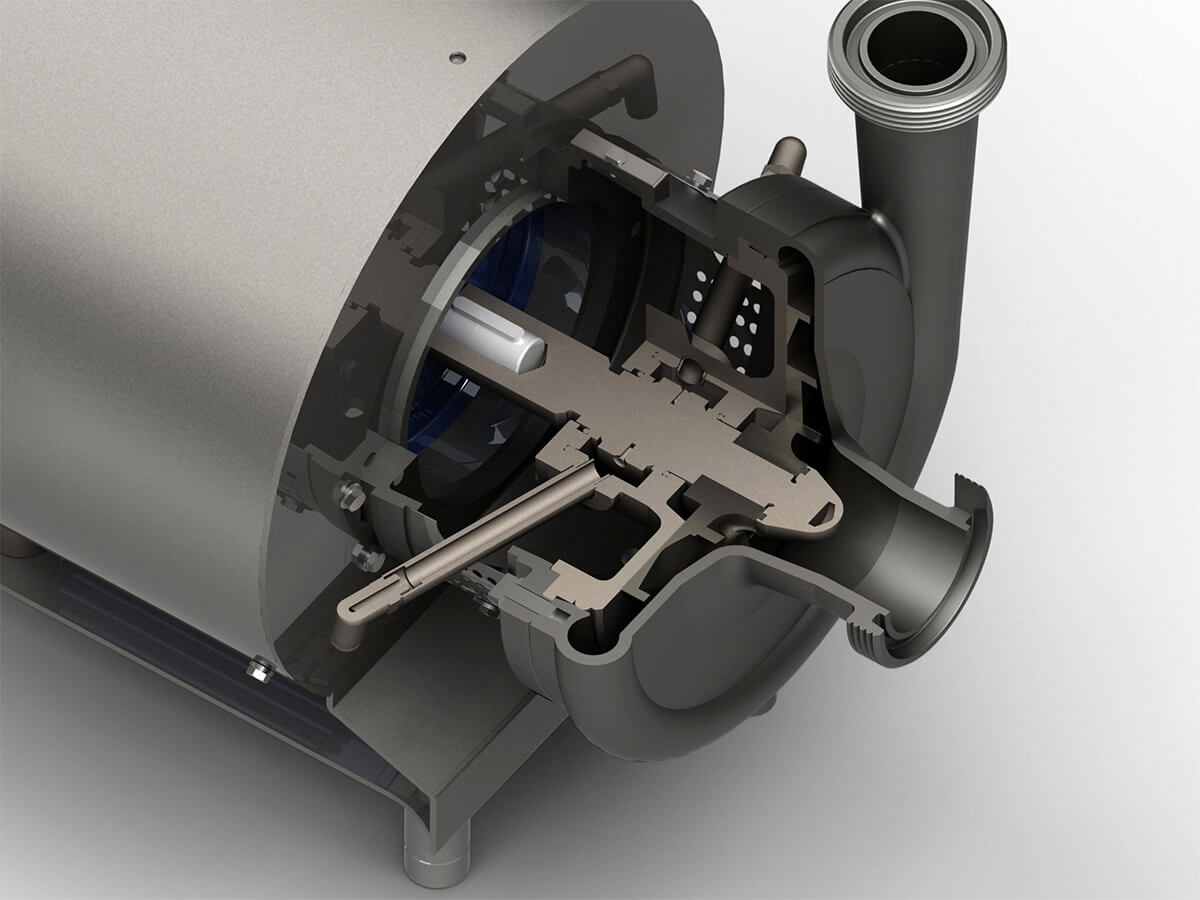

- Assembly: on a horizontal or vertical plane

- Operating temperature: -25 +140 °C

Externally flushed centrifugal pumps

The construction of this type of centrifugal pump with a double-flow mechanical seal external to the desired one works exactly like other auto-flow pumps but allows the seal to be lubricated separately from the product that passes inside the pump body.

This allows us to control the temperature independently of the product, through two flushing tubes.

The double external flush seal guarantees longer maintenance intervals and is recommended for aggressive/chemical products, with high temperature products or with sugary products, where a normal seal tends to glue the faces.

Vertical centrifugal pumps

They are specific for the transfer and recirculation of liquids from containers, tanks or reservoirs. They are installed vertically with the motor placed above the level of the pumped liquid.

By doing so, the pump does not require specific and expensive seals that can be a source of problems due to the leakage of liquids, thus preserving the life of the motor.

The horizontal LED marker is halved, compared to a traditional centrifugal pump. The suction, rotatable by 360°, allows the connection directly to the floor.

On demand

Pump tests with inverter and the possibility of requesting the test certificate with head-flow and flow-absorption graph.

Customized pump curves to maximize the potential of the electric motor.

Application of IP69K stainless steel motors of our production in order to exclude the application of casings to standard motors and pursue a hygienic solution.

If you have any special requests, we’re open to take them into consideration.