HYDEC – Where hygiene matters

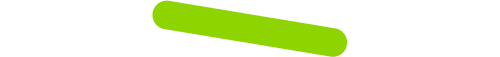

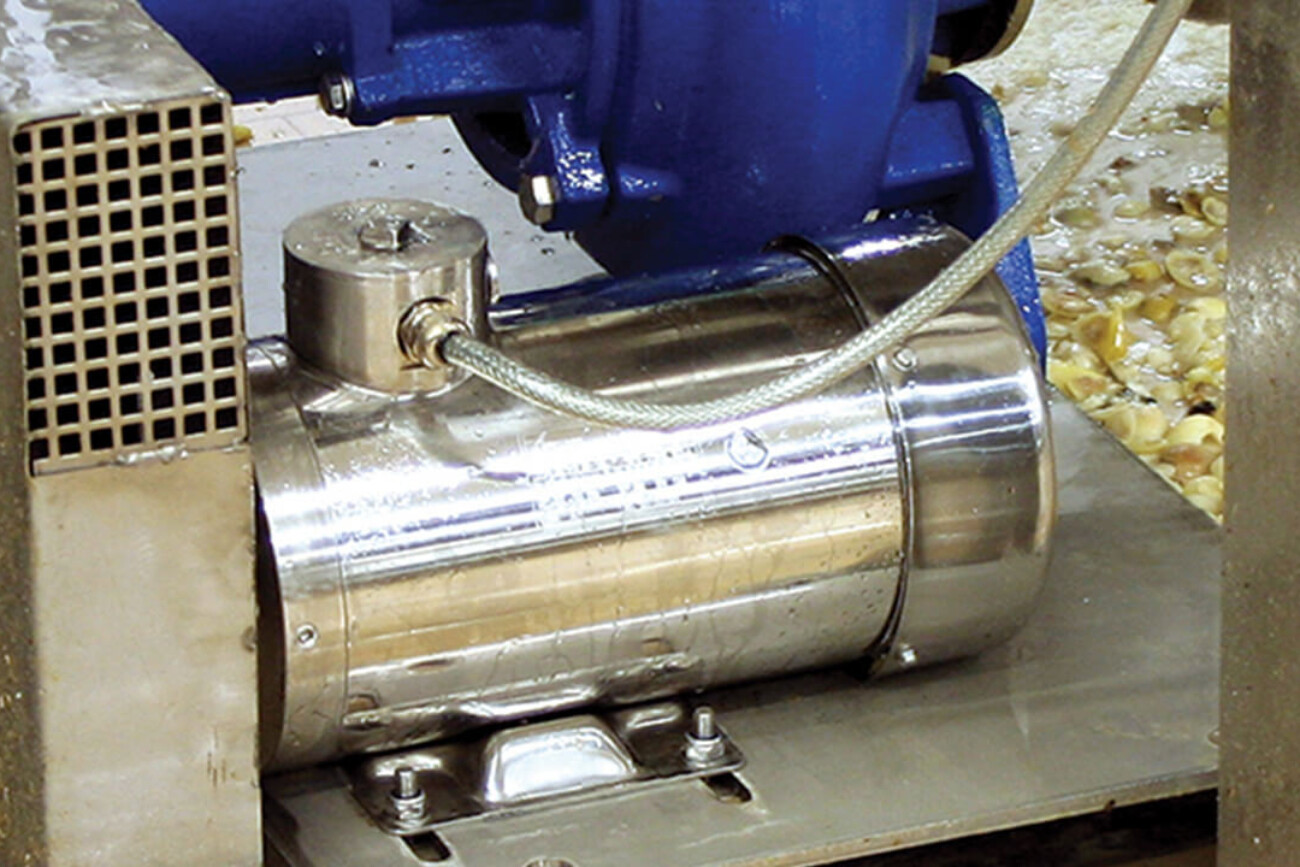

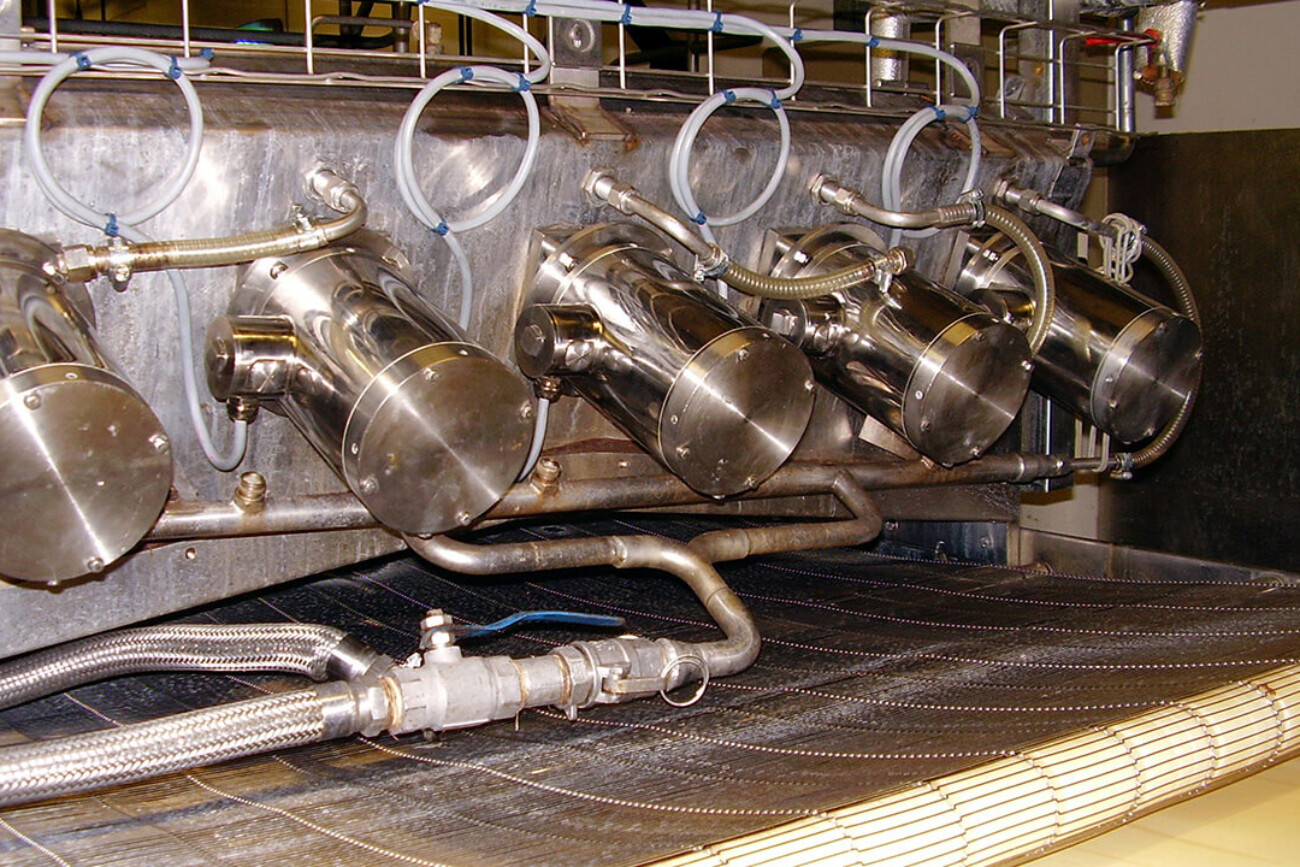

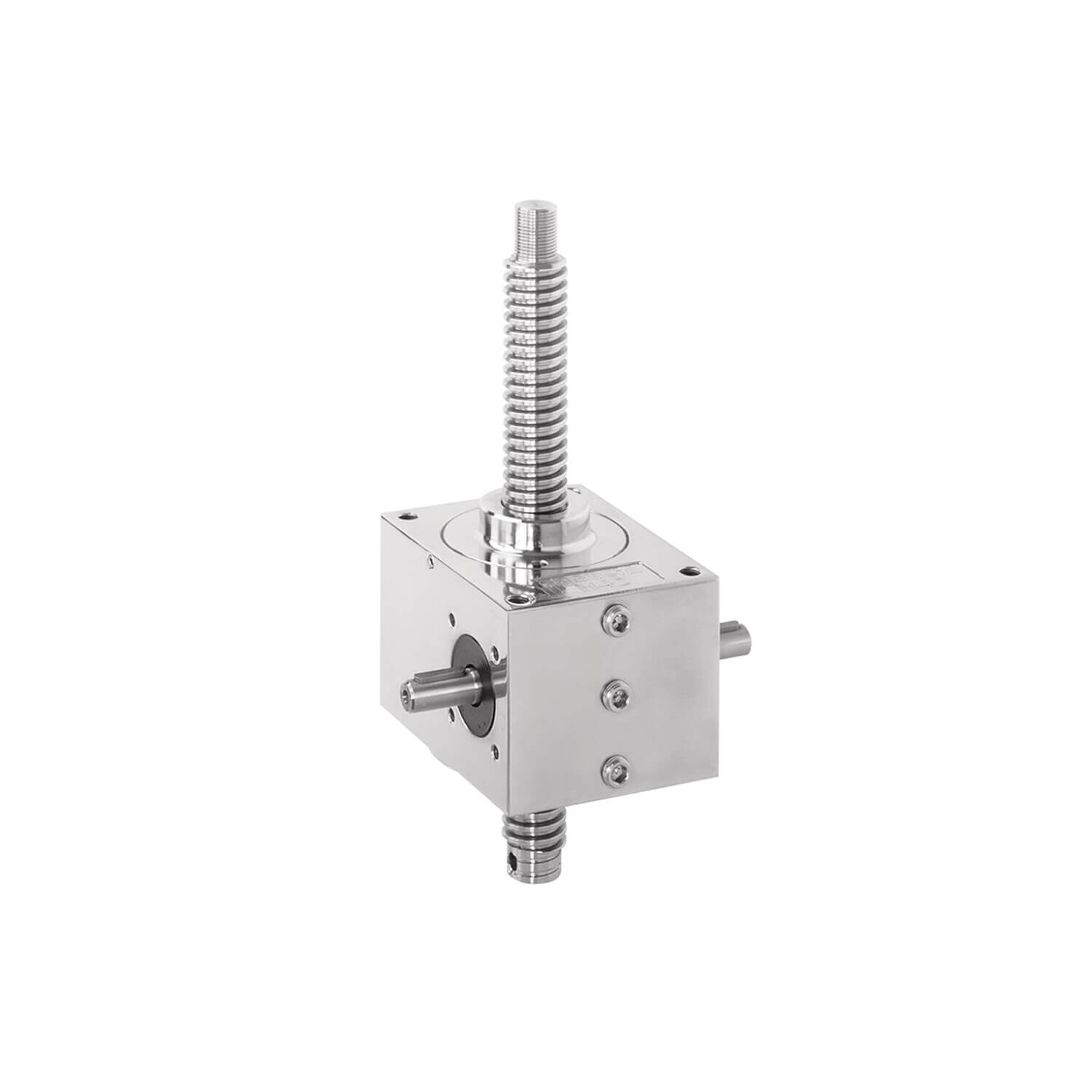

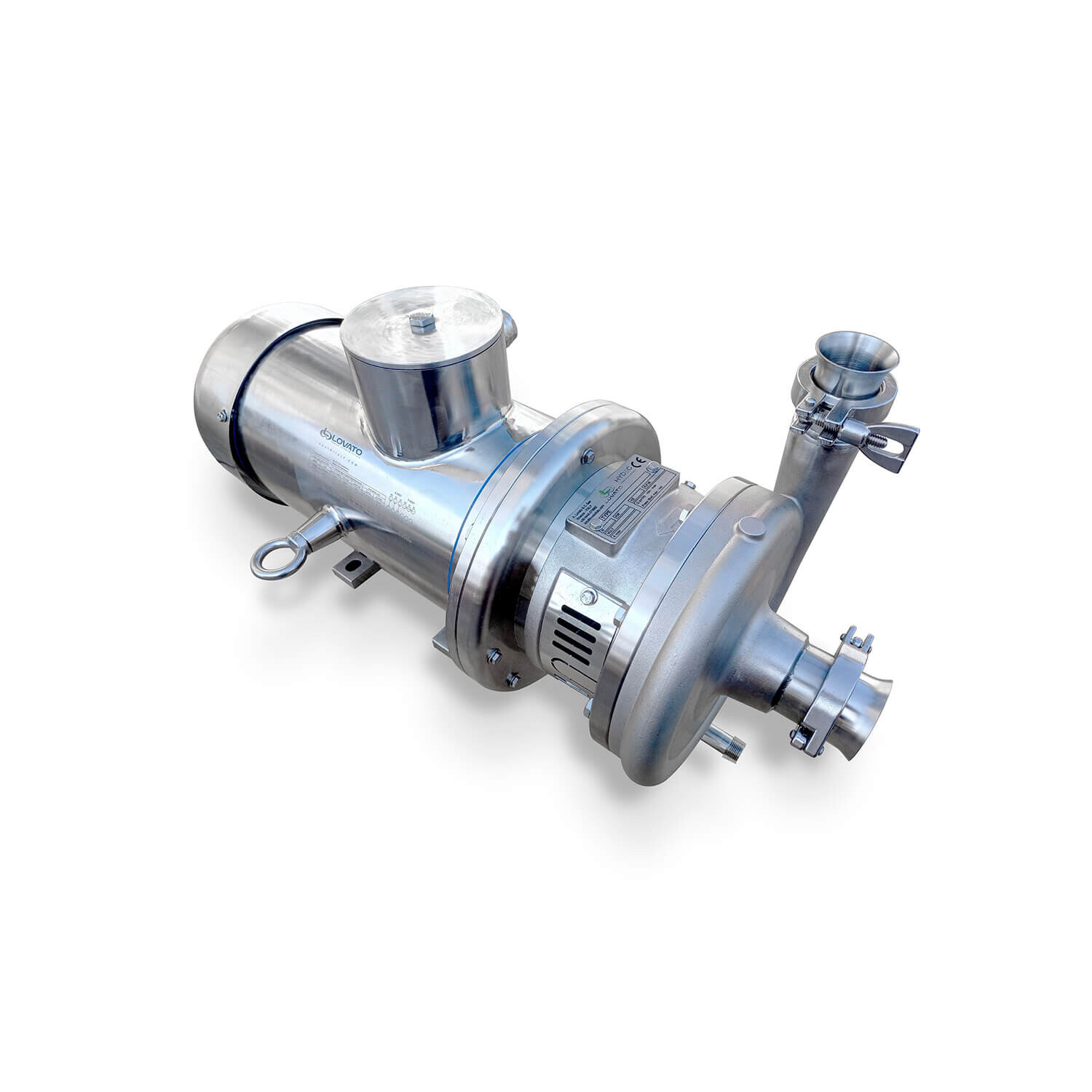

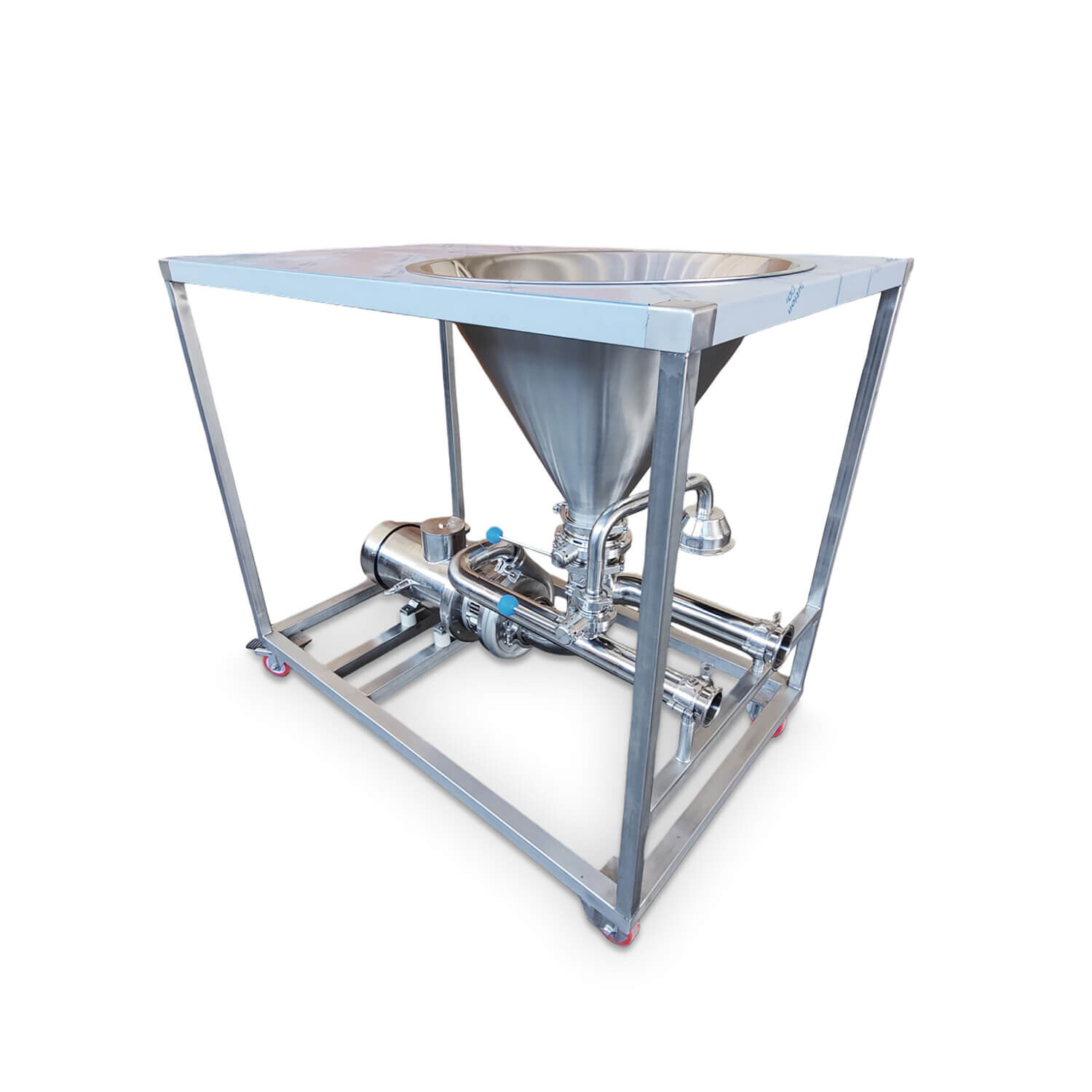

In compliance with the hygienic design guidelines, the entirety of our premium range of electric motors, gearboxes, variable speed drives, screw jacks, bevel gearboxes, centrifugal pumps, powder dissolution systems (Triblender), stainless steel supports and accessories have smooth and even surfaces to avoid material deposits.

Features

- Smooth and even surfaces to avoid material deposits

- Free of paint or surface treatment to avoid any possible peeling or contamination of the final product.

- Technical data are engraved on the body of the product so that there is no area for bacterial proliferation, which could occur with a regular plate (as well as the possibility that rivets could come off).

- Threaded fixing holes that are present on the body but not used are sealed with specific inserts provided by us.

Suitable for CIP and SIP application, as well as high-pressure washing

Our products, thanks to the high IP protection, represent a solution that is ideal for CIP (Clean in place) and SIP (Sterilization in place) applications and high-pressure washing (even when water at high temperature and/or aggressive detergents are used), in a humid environment and at all sites where on-site cleaning is expected, ensuring the efficiency of the gearmotor over time.

Benefits for the end user

- Complete solution from a single supplier.

- Better food safety.

- Simpler and faster cleaning: less required time for CIP (Clean in place), SIP (Sterilization in place) and high-pressure washing.

- Meet the standards set by new and rigid environmental rules by reducing waste, water consumption, as well as the impact of washing on local ecosystems (by reducing detergent consumption).

- Better efficiency thanks to the increased average interval between breaks. Solving problems that are specific to the application is also a factor that improves efficiency.

- Fast and easy disassembly.

- Low maintenance costs.

- Competitive advantage through innovative technology and savings achieved through lower costs.

Providing tomorrow’s standard, today.